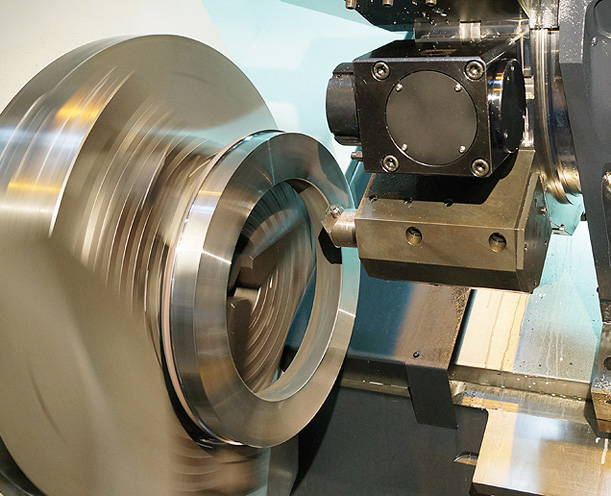

STOOSS SHAPES STEEL PERFECTLY

The cost-cutting reduction of the mechanical processing time is a great advantage for our customers. Our trained specialists shape each forging in rational single or series production accurately according to the customers‘ requirements, using modern machines, conventional and CNC center lathes, CNC vertical lathes, boring mills or milling machines. In addition, special processing such as flame cutting is used and the forgings can also be shot blasted at STOOSS.

MACHINING (CH)

CNC vertical turning lathe

| ∅ Outside | max. | 3'200 mm | |

| Rotating height | max. | 1'200 mm | |

| Weight | max. | 5 to |

CNC center lathe

| ∅ Outside | max. | 800 mm | |

| Turning length | max. | 4'000 mm | |

| Weight | max. | 4 to |

CNC boring mill

| Length | max. | 3'000 mm | |

| Width | max. | 2'000 mm | |

| Height | max. | 1'400 mm | |

| Weight | max. | 5 to |

CNC milling machine

| Length | max. | 1'525 mm | |

| Width | max. | 760 mm | |

| Height | max. | 625 mm | |

| Weight | max. | 3 to |