QUALITY AND MANUFACTURING TESTS

STOOSS forgings undergo various quality and manufacturing tests. Micrographic and chemical physical examinations, non-destructive and mechanical tests are carried out in the STOOSS laboratories. The test certificates, in combination with the ST-stamp, confirm the perfect quality of the STOOSS forging parts.

TESTING FACILITIES

Mechanical Tests

1 Tensile test machine

1 Impact test machine*

2 Hardness test machines

*Equipment for low temp. impact tests

NDT Equipment

Ultrasonic testing

Magnetic powder testing

Dye penetrant testing

Visual testing

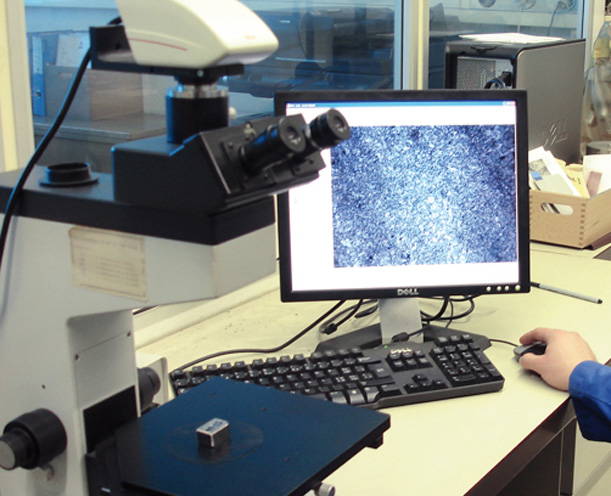

Laboratory

Macroetch and microetch tests

Corrosion tests

Spectroscopical identity test

Ferrit scope

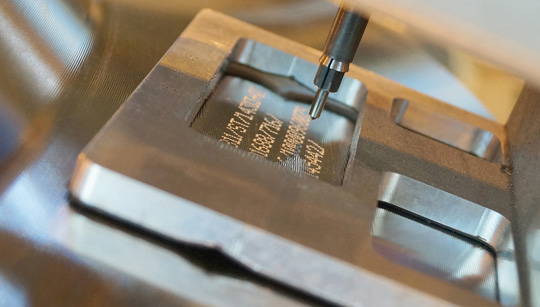

Dimension control

3D measuring machine

3D electrically measuring arm FARO

Safety and long product life

Forged parts from STOOSS are outstanding because of their:

material selected on the strength of its analysis and degree of purity

exact shaping

ideal degree of forming

optimum grain structure

minimum allowances, narrow tolerances

thermal treatment relevant to the application

Moreover, they offer exceptional advantages:

excellent manufacture in respect of surface quality and accuracy of form

suitable for processing on CNC

machines

reduction of mechanical processing time, thus saving costs

high degree of security against fatigue cracks